If Spindle is chosen as the aggregate offset, the cut path will appear on the screen to be offset by the amount designated in the Tool Length parameter.

The Plane Detect is not necessary, but if it is used, then the offsets will be set to 0.

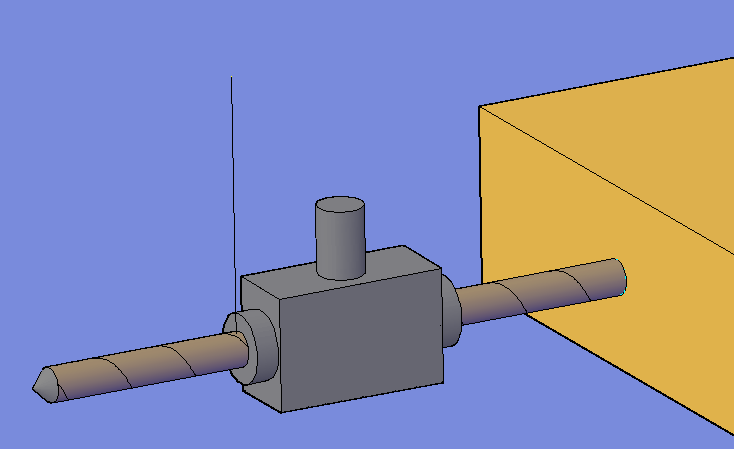

For an example of how this method would work, the following explanation is offered.

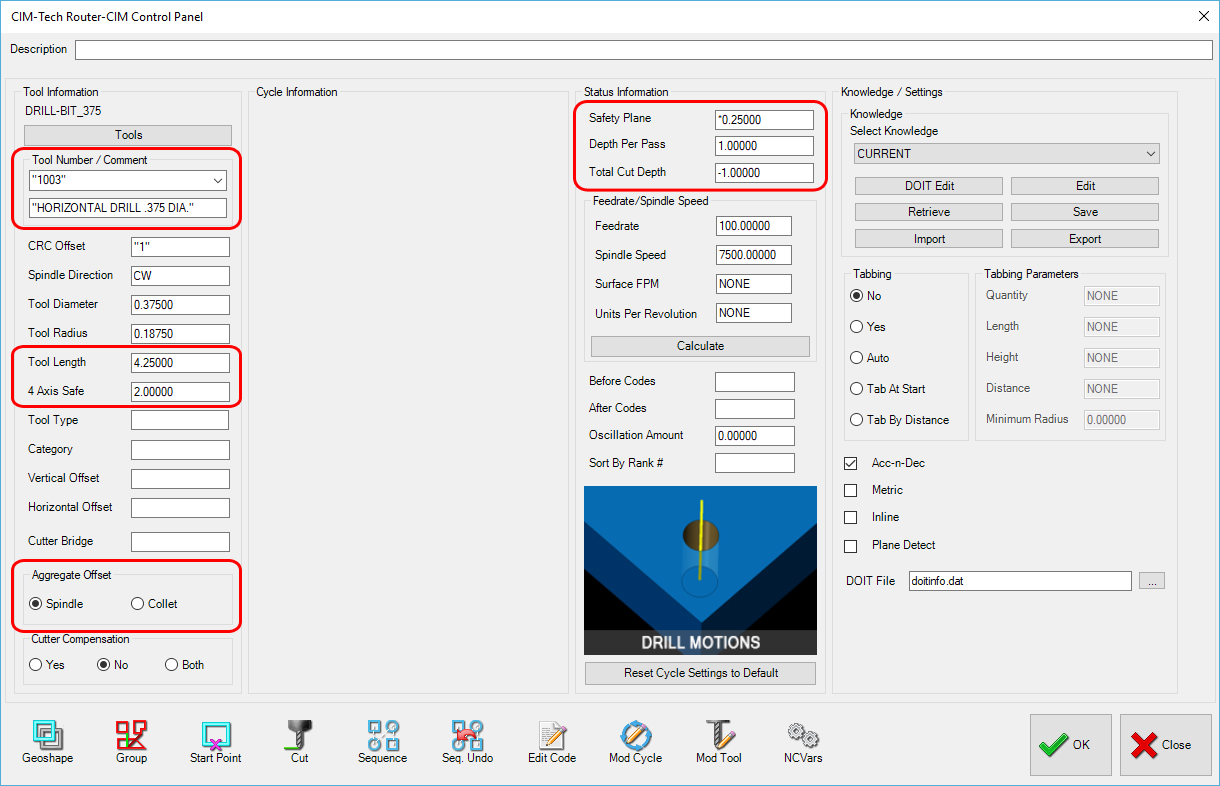

Looking at the picture below, the tools is a 3/8" Drill Bit, in a horizontal drill spindle.

The 4th axis Safe Plane is set to 2.0.

The Tool Length is set to 4.25.

The Aggregate Offset is set to Spindle.

The Safety Plane is *.25, and the Cut Depth is -1.0.

Horizontal Drill Example.

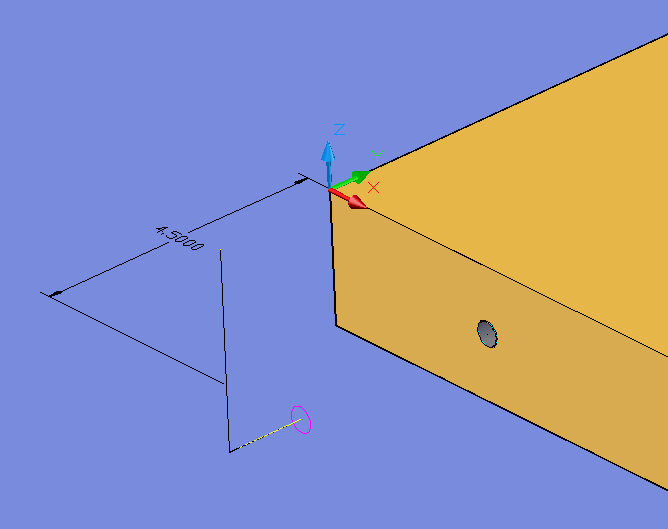

The effect of this is that the Tool Path will be offset from the geoshape by 4.5". This dimension is 4.25 for the tool length PLUS .25 for the Safety Plane.

Tool Path offset by Tool Length + Safey Plane.

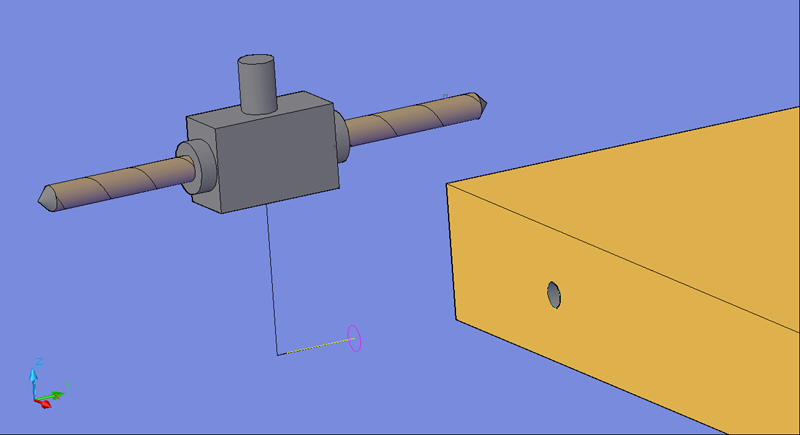

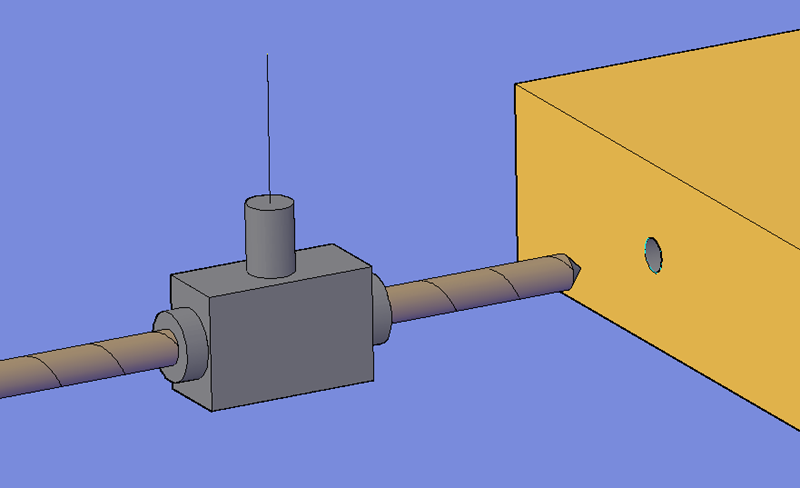

The tool path will represent the center of the drill block in this example. That means that the center of the drill block will move to the end of this tool path which starts at Z2.0 (4th Axis Safe) and the XY position 4.5 inches from the face of the drill hole.

Move to 4th Axis Safe

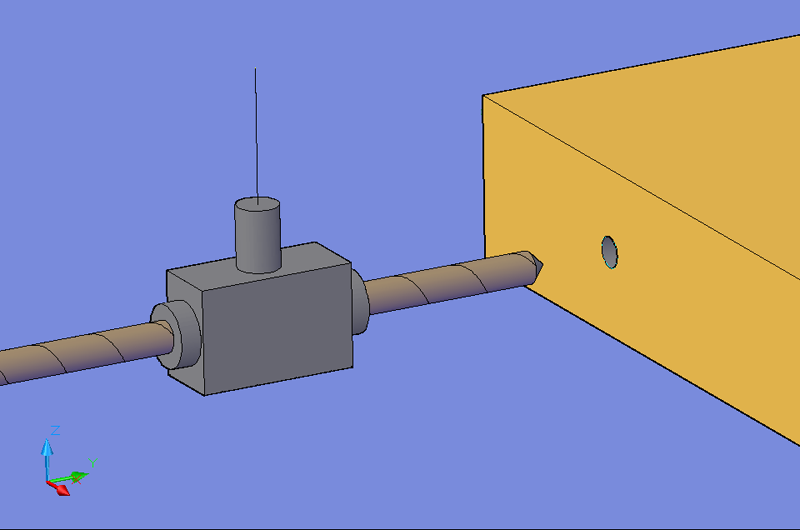

Next the tool will move straight down to the center of the drill hole in Z. It will still be .25 (Safety Plane) away from the center of the hole. This is the small black section of the tool path shown above. The tool will move from that .25 away from the hole, drill all the way to the bottom of the hole (1" into the material) and then move back out to the point 4.5 inches away from the center of the hole, then lift back up to the 4th Axis Safe point (Z2.0).

Move down to center of the hole, .25 away from face.

Here is the move down in Z to the center of the hole, still .25" away from the face of the part. This is a Rapid Traverse (G0) move.

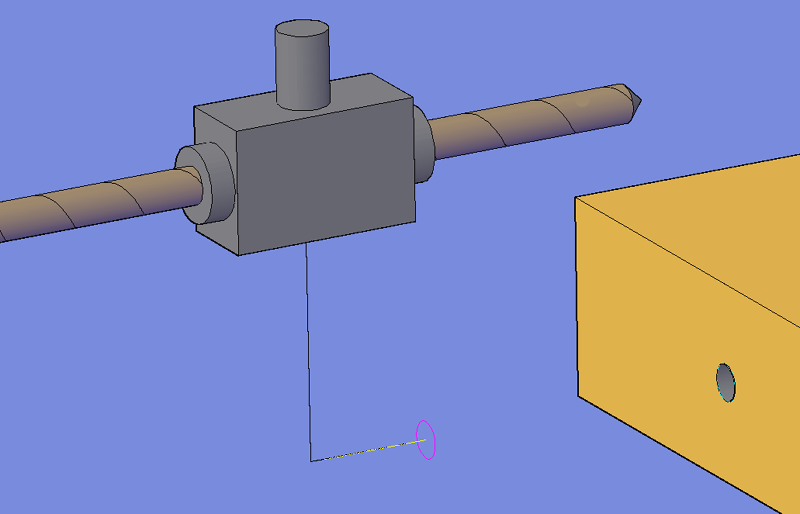

Next the hole will be drilled 1.0" deep...

Drill the hole.

Drill the hole 1.0" deep. This is a feed move (G1) at the programmed feedrate.

Next the tool will retract back to the Safety Plane.

Retract to the Safety Plane.

The tool retracts to the Safety Plane. This is a Rapid Traverse (G0) move.

Next the tool will raise back up in Z to the 4th Axis Safe.

Tool retracted to 4th Axis Safe.

And the tool is now retracted to the 4th Axis Safe. This is also a Rapid Traverse (G0) move.

This method only require that the programmer have an idea of the distance from the center of the spindle to the tip of the drill bit. That is an important measurement, but is really the only one required.

In the picture above, the tool path has been shifted by the value in the tool length field to emulate the spindle center, where the work coordinate or origin is set.