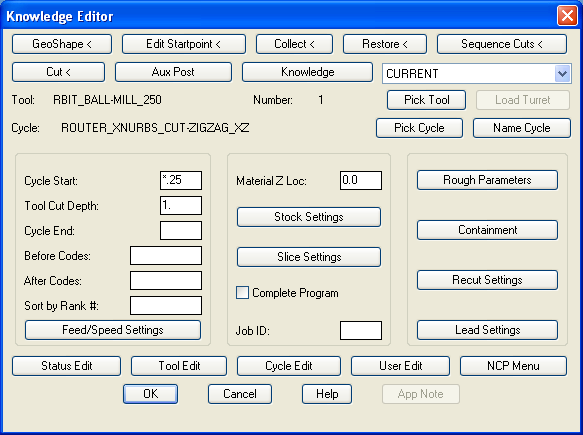

As you can see, the Control Panel changes into the Knowledge Editor when a NURBS cycle is selected. The NURBS configuration of the Knowledge Editor is customized to support the operation of the NURBS Cutter Cycle Editing. An explanation of the NURBS configuration of the Knowledge Editor follows.

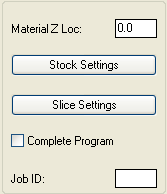

NC code files for 3D machining are generally very large by comparison to NC code found in production machining. Because these files, as well as supporting files, tend to be so large, it is common to make a machining operation a separate NC code file. A "Check" in the Complete Program Toggle, will create separate NC code files for each operation. NC code files can be combined using the NCSurfer "Process" function.

Geoshape and Edit Start Point can be used to control polyline direction and start point alignment when using Flow Cutting. Flow Cut Polylines must be going in the same direction. Closed Flow Cutting requires Start Point alignment. The Router-CIM command NCREVDIR will reverse the direction of Polylines. Flow line toolpath follows the direction of the Flow Polylines.

![]()

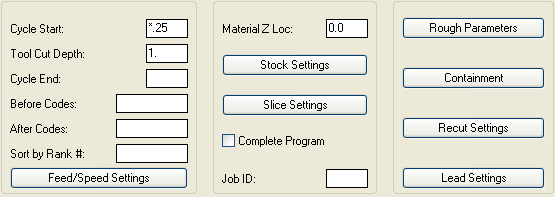

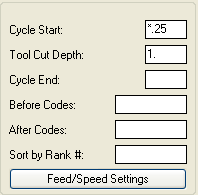

The Cycle Start entry defines the safe Z clearance plane. Tool Cut Depth is used as input for Project Cutting to limit cut depth per pass. Cycle End Position is ignored when using NURBS Cycles except when using Project Cutting. An entry in this parameter when using Project Cutting will control the depth of the final cutting depth.

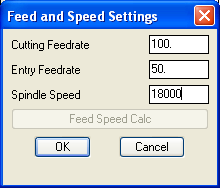

The Feed/Speed Settings opens an Edit Window for control of Cutting Feedrate, Plunging or Entry Feedrate, and Spindle Speed.

The Material Z Location entry indicates the location of the top of the stock material.

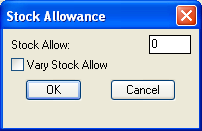

The Stock Settings Button opens an Edit Window for entry of Stock Allowance, sometimes referred to as finish allowance. A Check Box ON indicates that certain surfaces will require a different stock allowance(s). Multiple Stock Allowances are allowed.

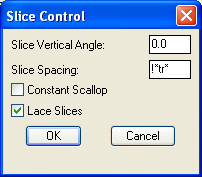

The Slice Settings Button opens an Edit Window for entry of Vertical Cutting Angle, Slice Spacing, Constant Scallop Toggle, and Lace or Zig-Zag Slices. If Constant Scallop is selected you are prompted for maximum scallop height during CUT. If Lace Slices is toggled on, toolpath will Zig-Zag. If toggled off, toolpath will be Unidirectional.

As stated earlier, a check in the Complete Program Toggle will cause the system to make NC code, including Start/End Codes. The Job Id entry will appear in the NC code.

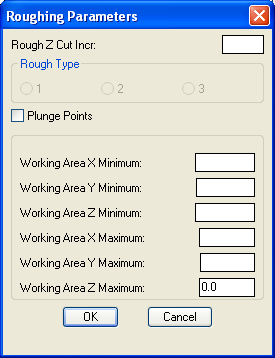

The Rough Parameters Button opens an Edit Window for entry of roughing parameters. Rough Z Cut Increment controls the maximum depth of each roughing pass. Rough Type controls the type of roughing motions desired.

A total of 6 roughing methods are available with the Expert NURBS Cutter. They are divided into two categories, Vertical and Horizontal. When the XZ or YZ Cycle is selected, you are in Vertical Cutting. When the XY Cycle is selected you are in Horizontal Cutting.

Plunge Points allows user selection of plunge locations. Always provide multiple plunge point locations. The system may create alternate plunge locations. Plunge points can be located inside or outside of the part.

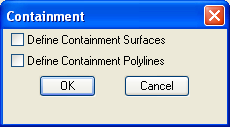

The Containment Button opens an Edit Window for selection of Surface Containment or Polyline Containment.

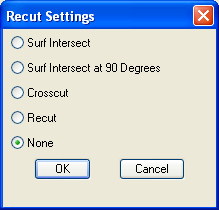

The Recut Settings Button opens an Edit Window for selection of Recut methods. Surface Intersect produces toolpath at surface(s) intersection(s). Crosscut produces toolpath on surfaces that meet angle criteria. Recut is used to produce toolpath, using a tool smaller than the previous tool, in areas that the larger tool could not access.

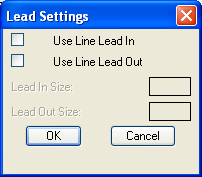

The Leads Button is to generate a line lead in and a line lead out of the tool path.

The Button opens an Edit Window for selection of Line Lead-In/Out's when using XZ or YZ Cutting. Lead size is controlled by the Lead Size entry. Leads do not apply to XY Roughing.

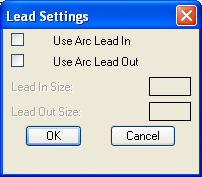

The Button opens an Edit window for selection of Arc Lead-In/Out's when using XY Cutting.

Vertical Slice Leads

Horizontal Slice Leads