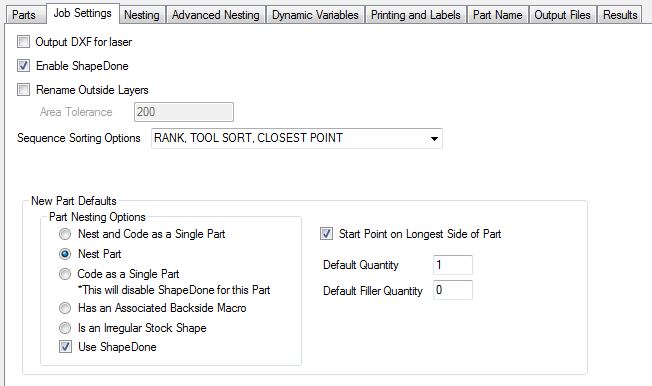

The Job Settings tab in a job contains the variables that affect various aspects of the job during the automation run. There are several sections to these settings.

Output DXF for laser

This option will create a DXF file of each nest or single part cut for a projection laser to use in order to show the layout of the parts on the table. If you do not have a projection laser, leave this option off.

Enable Shape Done

Enabling Shape Done will turn on Shape Done for the job. If parts have the option turned on to enable Shape Done, then a copy of the part will be stored with the knowledge drawing.

If this option is checked, the area tolerance is filled in, parts with less area than the amount listed will have the outside layer rename with a prefix of SML so that an alternate knowledge can be used on them. This is useful if you cut small parts and they tend to lose vacuum or move.

For example, if a part is less then the area you have indicated and this part has an outside layer such as OUTSIDE_0.7500, this feature will rename that layer to SMLOUTSIDE_0.7500. This way in the DOIT file you can make knowledge associations to the layer SMLOUTSIDE_0.7500 so that the small parts are machined differently then larger parts.

Sequence Sorting Options

You may select from any of the sorting options listed and that option will be used to sort all the parts in the job during Sequence.

New Part Defaults

Part Nesting Options

Nest and Code as Single Part

Checking this option will cause Router-CIM Automation Suite to nest each part in the job, and also make a separate NC program for each and every part on its own. This is useful for situations where a part is later broken or lost, a piece of material can be placed on the machine at the home position and run just the program for the one part.

Nest Part

When enabled, this option will cause Router-CIM Automation Suite to place every part in the job into a nested sheet based on the material specified. If more than one material exists for parts in a job, nests will be created for each sheet with the parts specified for that material.

Code as Single Part

Using this setting will cause Router-CIM Automation Suite to make a separate NC program for each part in a job. No parts will be nested together.

NOTE: For more information about 'Code as Single Part', please visit the 'Part Properties' section.

Has an Associated Backside Macro

When using macros, it is sometimes possible to have a macro for operations on the front of the part and also for operations on the back of a part. When this is true, enabling this option will allow one of the macros to be placed into a nest and the other side will be coded as a single part with a separate NC program. This option only works on macros, and the backside macro must have the same name as the front side but end in '-b'. For instance Style11.scn has an associated backside macro named Style11-b.scn.

Is an Irregular Stock Shape

If you have an irregular shaped piece of material that you want to use as a sheet to nest parts on, you may include that drawing in the job as a part and then set this option for that particular part. Router-CIM Automation Suite will not cut this shape, but will use it to nest parts in.

The geometry of the irregular stock sheet should be drawn on layer IR_STOCK.

Use ShapeDone

This option must be turned on in order for a part to be passed to the ShapeDone folder and stored.

General Options

StartPoint on longest side of part

Using this option will ensure that when new parts are added to a job, the Startpoint on longest side of part box is checked by default.

Checking this box will force Router-CIM Automation Suite to move the startpoint to the longest side of the part, regardless of where the startpoint exists currently.

Default Quantity

This field allows you to set the default quantity that parts are set to when they are added to a new job. When a new job is created, the number of parts that are set automatically will be set to this number.

Default Filler Quantity

This parameter is to set the default number of filler parts set for each new part in a job. If there is enough space in the nest, then these parts will be placed in the nest to fill the space and boost sheet yield, up to the number set in this section.